Review of the Literature on Feed Conversion Ratio of Animal Production Species

Feed represents between 60 and lxx % of the total cost of pork product in modern capital-intensive systems. Within feed, energy alone may stand for 50 % or more of the full cost [1]. Carbon-containing compounds in the feed, including fat, saccharide and poly peptide, release free energy when oxidized. Such energy is required for such processes as the biosynthesis of proteins, basic and lipids, for biochemical processes associated with maintenance, for active ion transport and for mechanical work [2].

Energy is the critical dietary constituent that supports maintenance, as well equally tissue accretion, and knowledge of energy metabolism and growth is essential to the understanding of feed efficiency [1]. In full general terms, the immature sus scrofa volition typically try to consume sufficient feed to come across its energy requirement for maintenance and growth. Yet, in many situations, feed intake is dumb by social, physiological, or environmental constraints. As a result, daily energy intake often falls short of that needed to support maximal gain. Consequently, feed and energy intake are highly circuitous subjects, and despite decades of inquiry, gaps in our understanding persist [3].

While feed efficiency strongly influences financial returns [4], due to its close association with feed costs, actions taken to improve feed efficiency tin can inadvertently lead to financial losses rather than gains. This is due to the fact that single-minded actions taken to amend feed efficiency may affect other aspects of the enterprise, not the least of which is the cost of feed. As one instance, genetic selection solely for improved feed efficiency may reduce growth rate [5]. Another case would exist increasing dietary free energy concentration; while this simple action will almost always increase feed efficiency, it could actually increase feed cost per pig and concurrently lower net income.

For such an important subject field, feed efficiency is oftentimes misunderstood, and there is lilliputian universal agreement on the all-time approaches to achieving optimal feed efficiency. Function of this defoliation arises from the unfortunate fact that the biological basis of feed efficiency is poorly understood [1]. There is also disagreement – and misunderstanding – on how to measure and express feed efficiency; for instance, expressing feed efficiency on a live weight gain basis tin effect in misleading conclusions [6]. Finally, it needs to likewise be recognized that effectively measuring feed efficiency tin can be extremely difficult.

Measuring feed efficiency

A mutual and simple definition of feed efficiency in the scientific literature is trunk weight gain per unit of feed consumed. Sometimes, feed efficiency is expressed on a dietary energy footing rather than feed intake. Although the concept is fairly simple, beneath it lays the potential for a multitude of practical errors. For example, feed consumed is rarely measured; feed disappearance is the actual measurement. Because of differences in feeder design and feeder adjustment, feed consumed and feed disappeared tin differ by x % and sometimes by equally much every bit 30 % [7]. It is therefore important to realize that feed disappearance does not necessarily accurately reverberate feed intake by the grunter and improving feed efficiency in a particular circumstance may exist every bit simple as feeder adjustment or redesign.

The weight range in which feed conversion is measured is as well of disquisitional importance [iv]. Animals of different weights take unlike requirements for maintenance; therefore, when comparing groups of pigs for feed efficiency, the variation due to differences in trunk weights at which various animals are evaluated must be taken into account. Equations that tin be used to adjust for differences in initial or final bodyweight are available [four]. This has implications in both research and commercial application. Unfortunately, many experiments are conducted to a mutual time endpoint, rather than a common torso weight endpoint, making comparison of feed efficiency across treatments very hard, if not impossible.

Energetic differences in diets can also introduce unexpected, or even unseen, errors. Some of this error can be due to inaccurate estimates of dietary energy or due to the energy system existence used for the measurement. Thus, differences in measured feed efficiency may be the consequence of unmeasured differences in dietary energy; this can get a particularly serious problem when diets widely varying in protein, lipid or cobweb content are being compared. Furthermore, variation in the composition of gain (fat, lean, or bone) and in related maintenance requirements prevents this measure from being a precise estimate of energy conversion rate. Maximum lean growth potential, besides as fat deposition rates, vary as a function of feed intake among genotypes and sex [8]. Therefore, the about useful criteria to evaluate feed efficiency in meat producing animals should exist the corporeality of edible product achieved with a given energy intake, rather than the fraction of energy in the feed which was converted to total body weight [ix].

In studies of genetic variance and heritability, and especially in choice programs, traditional measures of feed efficiency treat animals with differing growth rates and differing mean body weights equally [9]. In an attempt to more finer compare private animals, Koch et al. adjusted feed consumed for rate of proceeds and for mean body weight; this new approach evolved in swine to measuring growth rate as well as body limerick and became known every bit residual feed intake (RFI). Residual feed intake is calculated every bit the difference between observed feed intake and expected feed intake, the latter based on the animal'due south rate of gain and trunk back fat content [nine, 10]. Animals with lower RFI are more efficient and animals with high RFI are less efficient.

Thus, measuring feed efficiency poses significant challenges that are often ignored in both enquiry and commercial settings. Failure to capeesh basic factors affecting the measurement of feed efficiency can lead to incorrect conclusions in the interpretation of data.

Expressing feed efficiency

Feed efficiency has traditionally been expressed on the basis of a ratio of feed consumed and growth achieved. More recently, other expressions of feed efficiency have been adopted. The option of the correct term is generally dictated by the cognition existence sought and the manner in which the information will be used to make decisions. It should also exist expressed on the basis of data in which there is the greatest confidence. The problem of feed wastage, previously discussed, is an obvious case.

A relatively elementary, but increasingly common, modification is the calculation of feed conversion on the basis of carcass gain equally opposed to total bodyweight proceeds [6, 11, 12]. This correction has evolved with the increasing use of higher fiber diets which are associated with changes in dressing percentage concurrent with pigs being sold – and paid for – on a carcass weight basis. Consequently, differences in dressing percentage tin accept a substantial impact on net income. Pigs arrange to the feeding of higher fiber diets by increasing viscera weight and volume [13]; this not but alters carcass dressing percentage but it also increases energy and amino acid requirements, which further impairs feed efficiency [14, xv]. One of the challenges of expressing feed efficiency on the basis of carcass proceeds is access to data on dressing percentage at both the start and the end of the report. The latter is easily measured straight, simply the former is often estimated, incorrectly, equally the same dressing percentage measured at harvest. Generally speaking, dressing percentage increases as the pig grows, due to the fact that the total body of the pig grows at a higher proportion than the viscera [sixteen, 17].

Feed efficiency can too be expressed on the footing of energy consumed rather than feed consumed [1]. This approach has the advantage of placing increased focus on the efficiency with which dietary energy is used by the sus scrofa. This, in plow, is valuable considering energy is by far the greatest contributor to the cost of the diet [2]. Still, it also has its weaknesses, not the least of which is the inaccuracy of estimating the concentration of free energy in the diet. The start level of mistake occurs in quantifying dietary free energy concentration, which is rarely determined biologically and all also often is a volume value that may or may not reflect the truthful free energy content of the ingredient (due south) in the nutrition. The second level of mistake is the method of expressing dietary energy concentration. Much of the world continues to use digestible energy or metabolisable energy, despite the fact that both contain errors due to the variation in efficiency with which differing sources of energy – poly peptide, fat, cobweb and starch – are used for maintenance and for gain [8]. Information technology is therefore very believable that differences observed in feed efficiency are simply artefacts of an inaccurate free energy system rather than existence due to whatever real change in efficiency with which the pig uses available energy.

Increasingly, at that place is a desire to represent feed efficiency in financial terms because fundamentally, the goal of pork product is to use feed resources most efficiently and effectively, and that means generating the nearly favorable net income. Thus, preferred expressions of feed efficiency in financial terms include feed toll per pig sold, feed cost per kg of alive weight gain, feed cost per kg of carcass weight gain and return over feed cost. None of these calculations addresses the bear upon of growth rate on financial efficiency; the solution is to expresses each of the above on a per pig place, rather than per pig basis.

Biological footing of feed efficiency

Energetics and the utilization of energy for maintenance versus gain

Maintenance is a significant component of daily energy intake in the pig. It has been estimated that in a typical 70 kg pig offered feed on an advertising libitum ground, well-nigh 34 % of daily energy intake is directed to maintenance [2]. Consequently, minimizing maintenance costs to maximize the proportion of daily nutrient intake directed towards growth volition ameliorate feed efficiency and therefore must be a target in pig meat production. This will include minimizing the energetic price of unnecessary social stress, maintaining the sus scrofa in its thermo-neutral zone, and minimizing the impact of disease on the hog [i]. Well-nigh of the efforts directed at increasing efficiency in pig meat production have focused on genetic selection towards increased leanness. This effect, yet, volition reach a plateau when economically optimum levels of leanness in the pig carcass are achieved. Therefore, further efficiency increases may likewise come from a reduction in overhead costs, either past a further increment in growth rate (reduction of the time to reach harvest weight), efficient manipulation of nutrient partitioning towards growth (due east.g., regulators of nutrient sectionalisation such equally somatotropin), or by decreasing the overall maintenance requirements per unit of metabolic trunk weight of a growing pig [xviii]. However, there is no universal agreement in the literature on the influence of the production organisation on maintenance requirements, and consequently, the importance of reducing maintenance costs for improvements in feed efficiency. This was illustrated by Bauman et al. who concluded that selection based on genetic merit for milk production in dairy cows does not influence the maintenance requirement, and that differences in the maintenance requirement per unit of metabolic trunk size correspond only a small component of the differences in productive efficiency among cows [xix, 20].

Effect of feed intake on limerick of proceeds

Growth requires a substantial quantity of nutrients to support tissue maintenance and degradation. Before estimating whatever nutritional requirement of a given pig genotype, information technology is essential to understand the process of growth, which will in turn dictate the requirement. Feed intake is of import to consider considering it dictates the magnitude of changes in daily growth of lean and fatty tissues, and carcass quality in meat-producing animals [21]. Protein growth responds linearly to feed intake upward to a maximum signal at which it plateaus, the so-chosen PDmax [22, 23]. Pigs with high feed intakes reach the plateau earlier in life, and daily nitrogen retention is therefore constant over a wide range of live weights thereafter [24]. Similar observations have been reported in male turkeys where growth rate was accelerated to a plateau early in life, and this charge per unit did not farther increase but held at a relatively abiding daily gain until reaching 70 % of the mature body weight [21]. Lean growth increases linearly with feed supply merely reaches a plateau at the maximum lean growth potential of the animal. Notwithstanding, improved genotypes or dissimilar sexes may show greater growth rates. The entire male, for example, has a much greater potential for lean tissue growth than either the female or the castrated male person [25]. These differences can only exist seen at greater feed intakes. In poultry and in ruminants, differences in growth rates are also influenced by sex and are much more evident at high feed intakes [22].

During the growth phase when there is a linear lean accretion response to energy intake, it is believed that the animate being prefers to target lean while maintaining a minimal level of fat proceeds [21]. Certainly, this is how about models partition dietary free energy; after maintenance needs are accounted for, and the energy required for lean accretion is adamant, the remaining energy is assigned to lipid accretion. In this way, lipid accretion rates tin can be estimated for whatever genotype in which the protein deposition bend is known and daily energy intake is also known [26]. However, when free energy intake is severely restricted, a minimum lipid:poly peptide accretion ratio is observed [27]; this appears to be genetically coded. As energy intake increases, both protein and fatty deposition volition increase. The rate of protein accretion per unit of measurement of energy intake is typically linear until PDmax is achieved. This is often the signal of maximum production efficiency, considering growth rate is high and considering if energy intake farther increases, only lipid is deposited onto the carcass [17, 26].

Residual feed intake

Residual feed intake (RFI) is a measure of production efficiency defined as the deviation between the observed and expected feed intake of an individual based on growth and backfat [28]. Pigs divergently selected for RFI consistently demonstrate differences in carcass composition and in feed intake. Low RFI pigs had less carcass fat, consume less feed and exhibit similar or slightly slower rates of gain compared with high RFI pigs [x, 28, 29]. In the Iowa State Academy herd, vii generations of option for low RFI resulted in a reduction in ADFI of 0.6 kg/d with only a small reject in growth rate compared to the loftier RFI line. This corresponds to an increase in feed efficiency of 35 % [28]. Harris et al. reported that selection for low RFI alters nutrient utilization and free energy digestibility, also as improving nitrogen and phosphorus balance [30].

The flux through pathways of protein deposition, which include calpain and the ubiquitin-proteasomal system within musculus, are decreased in the low RFI line [31]. Additionally, genetic pick for low RFI may result in a decrease in oxidative stress due to a reduction in both electron leakage and product of reactive oxygen species from mitochondria in muscle and liver tissues [32]. Therefore, role of the improvement in feed efficiency in low RFI pigs could be explained by the lower rate of protein deposition and by reduced oxidative stress.

Carcass composition and meat quality

Concern has been expressed that pigs highly selected for improved feed efficiency may produce pork which is of inferior quality. Compared to a random control, carcasses of animals selected for low RFI had [29, 33, 34] or tended to have less back fatty [28, 35]. French data indicated that selection for low RFI lowered postal service mortem pH and resulted in slightly poorer meat quality [36]. The French researchers also reported that h2o belongings capacity was reduced [33] and sensory quality was dumb [34] in depression RFI pigs. These results differ somewhat from that reported past Iowa Land University researchers [35]. Smith et al. found that pork from low RFI pigs did not differ from controls with respect to drip loss or purge loss and expressed minimal color changes. However, the authors also reported a correlation betwixt selection for RFI and decreased sensory traits related to reduced intramuscular lipid and a subtract in post mortem proteolysis of myofibrillar proteins such as desmin.

Susceptibility to immunological stress

It is well known that pigs exposed to pathogens respond with reduced feed intake and consequently growth rate [37, 38]. Exposure of an brute to pathogens triggers a shift in its metabolic priorities to mount an appropriate allowed response. Under pathogenic challenge, pigs require nutrients for functions that enable them to defend; some of these functions include: i) innate immune response, 2) replenishment of damaged or lost tissue (plasma, sloughed cells etc.) and 3) caused immune response [39]. Nether scarce resources due to lower feed intake, the grunter needs to allocate resources to fight the pathogens and operate the normal functions of a healthy grunter (e.g., maintenance and growth). One important fact to consider is that poly peptide becomes the get-go limiting resource in immune challenged pigs because many components of the immune response are rich in proteins [39]. It is likewise generally accepted that energy requirements are lower for growing animals during a health claiming [40], but there is too evidence of energy becoming limiting in pathogen-challenged pigs because of an increase in estrus production (fever) and activation of the immune response [39]. The functions of immunity may increase the maintenance requirement, and are prioritized over functions of growth in terms of nutrient allocation [forty].

It has been theorized by some that choice for improved efficiency might brand pigs more susceptible to disease. Rakhshandeh et al. evaluated the affect of a repeated LPS (lipopolysaccharide) claiming on both loftier and low RFI lines [41]. They observed no differences in apparent ileal digestibility of nutrients (Assistance), but did discover an increment in apparent total tract digestibility (ATTD) under this modelled immune challenge. They did not see any impact on intestinal nutrient ship or barrier function. Divergent pick for low RFI increased credible full tract digestibility of nutrients, but it had no effect on apparent ileal digestibility of nutrients. However, immune organization stimulation affected both AID and ATTD of dietary nutrients and may exist a major source of variation in feed efficiency amid individuals. Birthday, genetic pick for LRFI appears to reduce the full tract digestive chapters of growing pigs during immune arrangement stimulation. Withal, additional information are required to confirm these findings.

Improving feed efficiency

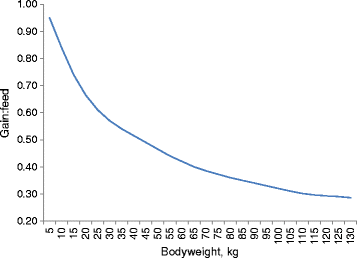

Feed efficiency is a part of body weight [42], and so every bit the squealer grows toward market weight, it becomes less efficient at converting feed into body weight gain (Fig. 1). Nonetheless, at a given weight, feed conversion tin can exist affected by numerous internal and external influences, as previously described. Understanding and controlling these elements provides the scientific foundation for achieving improvements in feed efficiency. Internal factors of particular interest include maintenance processes, body composition and health status. External factors include the nutrient and ingredient composition of the feed, the mode in which the feed has been candy, the thermal environment in which the squealer lives, access to feed and water and the use of diverse feed additives.

Relationship betwixt body weight and feed conversion

Internal factors

About one-third of the variation in feed conversion amongst animals is related to processes unrelated to the charge per unit and composition of growth [43]. Consequently, efforts directed at improving feed conversion must consider these maintenance processes. Some, such as basal metabolic charge per unit and body protein turnover charge per unit, are under at least partial genetic command [43]. Others are related to activity, which van Milgen et al. [44] reported to be proportional to protein mass in the torso, and thermoregulation which changes in a curvilinear style according to the deviation from the grunter's thermal comfort zone [45].

Allowed function is frequently considered a component of maintenance requirements, although classical definitions exclude information technology. Nonetheless, host-pathogen interactions place significant free energy demands on the animal as a result of a multi-faceted response to infection [46]. Minimizing demands placed on the pig's immune arrangement is an constructive way to meliorate feed efficiency [47].

Body composition is fundamentally a function of sex activity and genotype, along with prior nutritional regime and health status. It is well documented that entire males are more than efficient than females, which in turn are more efficient than castrated males [26]. However, at the present time, most producers have little control over the gender of the animals they are raising. Sex activity choice applied science applied to sperm was outset demonstrated in 1989 [48], but in swine faces considerable technical challenges earlier information technology can be applied widely [49]. Selection of pigs with no or reduced androstenone, forth with the implementation of dietary regimes that minimize skatole production, the two essential contributors to boar taint, is another approach being pursued [50]. Finally, immunological castration offers another tool to allow the feeding of more efficient intact males rather than castrates while addressing concerns almost pork quality and behavior [51]. At the present time, there appears to be limited market penetration for this engineering science, but information technology has accomplished success in selected markets. Therefore, at the present time commercial pork production will proceed to exist based on traditional castrated males and females, although this is likely to alter in the future – with attendant improvements in feed efficiency.

Factors external to the pig

It is well known that increasing the concentration of energy in a diet will virtually e'er effect in improved feed efficiency Tabular array ane [52, 53]. If no comeback is observed, it means that a nutrient deficiency is impairing the pig's power to reply to the energy, or that ingredient energy values are incorrect.

While increasing dietary energy is almost guaranteed to amend feed efficiency, there is a surprisingly poor correlation betwixt energy concentration in the diet and feed efficiency when measured among farms, amongst experiments, or among widely differing diet weather condition. Oresanya et al. reported a correlation betwixt daily DE or NE intake and feed efficiency of but 0.12 to 0.14 [54]. The reason for this discrepancy rests in the diverseness of factors that can influence feed efficiency, the inaccuracy of measuring feed efficiency, the imprecision of quantifying dietary energy concentration and unproblematic animate being variation.

Restricted feed intake is practiced in some parts of the world to achieve 2 objectives: to improve carcass quality past reducing fat content, and to improve feed efficiency. This practice improves feed efficiency through the reduction in body fat, although the do good is offset somewhat by the slower rate of growth. The energetic toll of protein deposition in the body is about 10.03 kcal ME/kg, while the comparable value for fat is xi.65 Mcal ME/kg [2]. On this ground, fat deposition requires xvi % more than energy per unit of measurement of gain. However, protein accession is accompanied past water deposition in lean proceeds, in a ratio of about 4:one, and so the actual advantage of lean accession is greater than iv:1 over fat [55]. In most major pork producing regions, limit feeding is not practiced because it lowers growth charge per unit and thus barn throughput, a key contributor to overall farm profitability.

Feed brake may besides better feed efficiency by reducing feed wastage. This occurs because pigs are more than probable to waste feed if it is in abundant supply.

There tin exist circumstances where restricted feed intake fails to improve feed efficiency. When brake is and then astringent that growth rate is seriously reduced, the additional days required to accomplish market weight also increases the number of days of maintenance required, such that the savings due to improved efficiency of gain, due to an improved ratio of gain of lipid to poly peptide, is fully offset by the energetic cost of additional days in the barn Tabular array 2 [27]. This example illustrates the importance of conducting enquiry to constant final trunk weight in order to effectively compare feed efficiency outcomes.

The management of feed processing can substantially influence feed efficiency. Numerous studies have reported near linear relationships betwixt grain particle size and feed efficiency [56–58]. In that location is too a proffer that reducing the standard deviation of particle size will too improve the digestibility of the diet, although more enquiry is conspicuously required on this understudied tropic Tables three and 4 [59].

The want to maximize feed efficiency through a more than finely ground feed must be balanced confronting the cost of the boosted processing, potential difficulties with diet flowability and possible impacts on beast health, notably gastric ulcers [56]. Ulcers become a greater event when particle size falls below about 500 microns and when diets are pelleted.

The desire to further reduce particle size to less than 600 microns has resulted in issues with the flowability of diets, which in plough impacts manufacturing, transportation and delivery of feed. Equally a effect, and ancillary with unusually loftier feed costs since 2009, many pork producers and feed companies in North America switched from brew to pelleted diets, something adopted by European producers many years before due to their college feed costs.

Pelleting provides a clear benefit in terms of feed efficiency [threescore], just the real advantage of pelleting is confounded by particle size. It is well understood that the do good of pelleting is greatest when particle size is big, and declines as particle size diminishes [60]. Furthermore, the value of pelleting is maximized when fines are minimized, but achieving consistent pellet quality is challenging [61]. Stark has suggested that numerous factors influence final pellet quality, and that nigh 40 % is related to the nutrition formulation, xx % to conditioning, 20 % to particle size, 15 % to die specification and 5 % to cooling [62].

The pig, like all mammals, is a homeotherm, pregnant that it can maintain - and indeed must maintain - a constant body core temperature across a relatively broad range in ambient temperature. This is achieved by adjusting heat losses and estrus production such that trunk temperature stay largely constant. Maintenance activities in the squealer provide nearly 70 to 72 % of total heat production at thermoneutrality [63]. The efficiency of utilization of dietary free energy depends on the substrate; fat and starch are more efficient than protein and fiber. Thus, utilization of higher fiber or higher protein diets in the warm summer months is contra-indicated since they will generate more rut during metabolism. If backlog heat is produced past the body of the pig, information technology will typically respond past reducing feed intake in an attempt to lower heat production and thus reduce the metabolic expense of dissipating heat from the body. On the other hand, if the squealer is housed in chilled weather, diets higher in poly peptide and fiber could be beneficial due to the thermic effect of feed. Clearly, the composition of the nutrition, as information technology relates to heat increase can contribute to improvements or reductions in feed efficiency.

The pig's environment will accept a substantial touch on operation. For example, if the temperature drops below the pigs' lower disquisitional temperature, feed intake will increase by 1.five % per °C [26] and feed efficiency will become poorer [64]. The lower critical temperature of the pig is estimated to be nearly 23 - 24 °C at 25 kg trunk weight, dropping to nearly 15 °C at 100 kg [64].

These lower critical temperatures (LCT) assume that the pigs are healthy, the floor is dry and at that place are no drafts. They too assume that the befouled is well insulated. If any of these situations exercise not exist, the LCT will be increased past mayhap 2 to 3 °C to accommodate the chilling impact of dampness, drafts, etc. Also, if pigs are non good for you – and therefore not eating to their full potential – their LCT will exist much higher.

The limited data that are available suggest that feed conversion is minimally affected by elevated temperatures in the befouled. As pigs go heat stressed, feed intake volition pass up by virtually 1 % (growing pigs) and 2 % (finishing pigs) for every degree above the upper disquisitional temperature [sixty]. The decline in feed intake is manifested in slower growth, such that changes in feed efficiency are surprisingly small [65].

Delivery of feed to the squealer may also play an important part in improving feed efficiency. Poorly designed feeders, combined with poor management of the feeders, can lead to excessive feed wastage and poorer feed efficiency, or to impaired feed intake. Feeders adapted too tightly tin can severely reduce feed intake and lengthen the time pigs spend at the feeder, thus reducing its capacity [66]. Feeder blueprint will make up one's mind if tight adjustment will amend feed efficiency, by reducing feed wastage, or simply reduce feed intake and thus animal growth. Optimum feeder adjustment will depend on many factors, but for dry feeders, 40 % coverage of the feeder pan with feed is currently recommended [66].

Inadequacy of feeder space may also effect in poorer feed conversion although Weber et al. reported no impact of feeder space until the pigs reached the concluding stage of grow-out prior to marketing [vi].

Source: https://jasbsci.biomedcentral.com/articles/10.1186/s40104-015-0031-2

0 Response to "Review of the Literature on Feed Conversion Ratio of Animal Production Species"

Post a Comment